Due to the investment of a large number of automation equipment, IISDOO can carry out 24-hour uninterrupted production and work in the peak season to ensure a stable production suppl. We can produce 80,000 sets of door handles per month.

Only production and supply are controlled in our own hands can we better control product stability and supply capacity;

IISDOO's production system consists of several production departments: installation workshop, die-casting workshop, CNC workshop, quality inspection workshop, material workshop, polishing workshop, warehouse workshop

Installation workshop

Function: The installation workshop is responsible for assembling

the produced parts into the final door hardware products.

Work content: assembly work, parts debugging, product testing, etc.

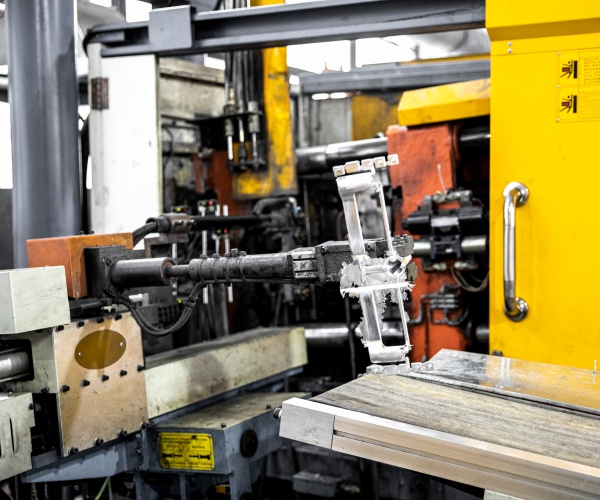

Die-casting workshop:

Function: The die-casting workshop is a place where metal or alloy die-casting is used to produce door hardware products.

Work content: mold making, metal smelting, die-casting, etc.

CNC workshop:

Function: The CNC workshop is a place where CNC machine tools are used for processing and manufacturing.

Work content: CNC programming, workpiece processing, parts processing accuracy inspection, etc.

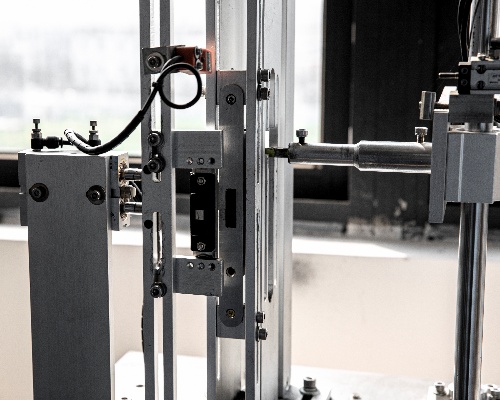

Quality control workshop:

Function: The quality inspection workshop is responsible for strict quality inspection and control of finished and semi-finished door lock hardware products.

Work content: inspect product quality, formulate quality standards, improve production processes, etc.

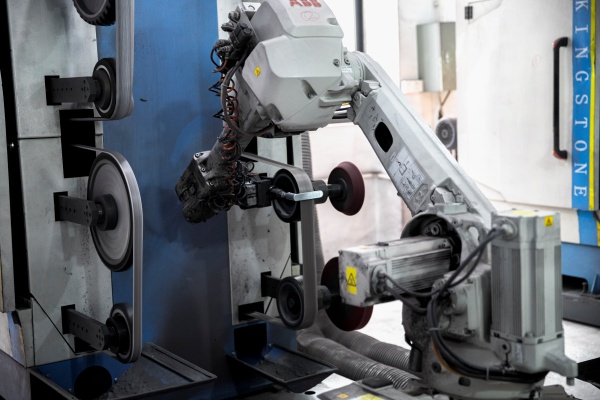

Polishing workshop:

Function: The polishing workshop is responsible for polishing the surface of the door handle to improve the appearance quality of the product.

Work content: polishing process design, polishing processing, surface quality inspection, etc.

Warehouse:

Function: The warehouse workshop is used to store and manage finished and semi-finished products.

Work content: warehouse management, cargo distribution, inventory counting, etc.

Each workshop undertakes different but interrelated tasks to ensure the smooth progress of the production process and the steady improvement of product quality.

Die-casting

Due to the investment of a large number of automation equipment, IISDOO can carry out 24-hour uninterrupted production and work in the peak season to ensure a stable production suppl. We can produce 80,000 sets of door handles per month.

Electroplating

We adopts 130℃ high temperature electroplating, which makes the finishing not easy to fade. In the situation that Chinese Government is getting more stricter with the environmental pollution, so more and more electroplating factories are shut down. Our electroplating factory invest a lot of money for the pollution disposal machines, making sure we are producing in green and we are friendly to our environment. In addition, the electroplating factory, is in the leading position in our area.

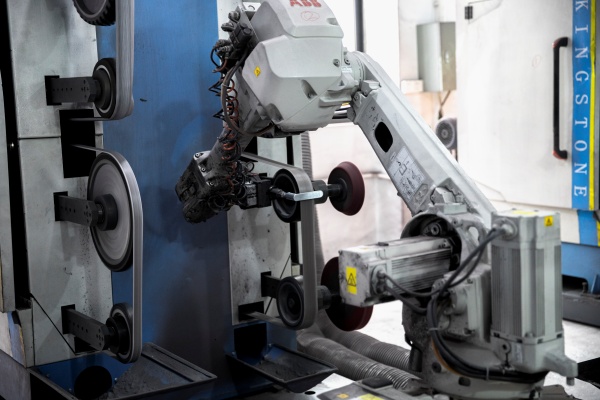

Polishing

Polishing is always important. We have our own polishing plant with around 15 experienced workers. First of all, we use rough (big abrasive grain) abrasive belts to polish the “flashes” and “gate marks”. Secondly, we use fine (small abrasive grain) abrasive belts to polish the shapes. Finally we use cotton wheel to polish the gloss surface. In this way, the electroplating will not have the air bubbles and waves.

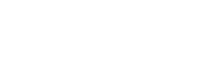

Automatic production

Since 2020, we have invested over 500,000USD for Automatic production equipment. Until now, we have sets of auto Cnc machine, 2 set of auto die casting machine, and 3 sets of auto drilling machine. In addition, we also invested 2 sets of auto polishing machine--Mechanical arm. In this way, all of our products could adopt same production standard. In busy season, due to automatic machines, we could become a 24-hours factory, to meet the customer's order requirements.

1 Stable surface finishing 72-96 hours NSS test for normal MSN, SBN, PC, Matt satin chrome and Black finish.

2 Testing in the In house testing We have testing team for in house testing every month, including salt spray test, cycle test, die casting parts testing, Daily simulation use testing.

3 Third party authoritative test We had pass the EN1906:2012 Standards and got the certification from Intertek

4 Quality management system In 2021, we got the Certification of ISO9001, in order to improving the production system and adopt a higher production standard.

5 IISDOO laboratory We has a laboratory with product testing machines inside, including salt spray test machines (anti-corrosion ability), cycle test machines (handle spring life cycle, mortise lock life cycle, cylinder life cycle), load capacity test machines (handle structure stability) and so on.