IISDOO only produces high quality hardware products

Throughout the entire manufacturing process, we operate a comprehensive quality monitoring system that covers every stage—from die-casting, machining, and polishing to plating, final assembly, and packaging. Each critical step undergoes stringent quality checks to ensure precision, durability, and consistency in every product we deliver.

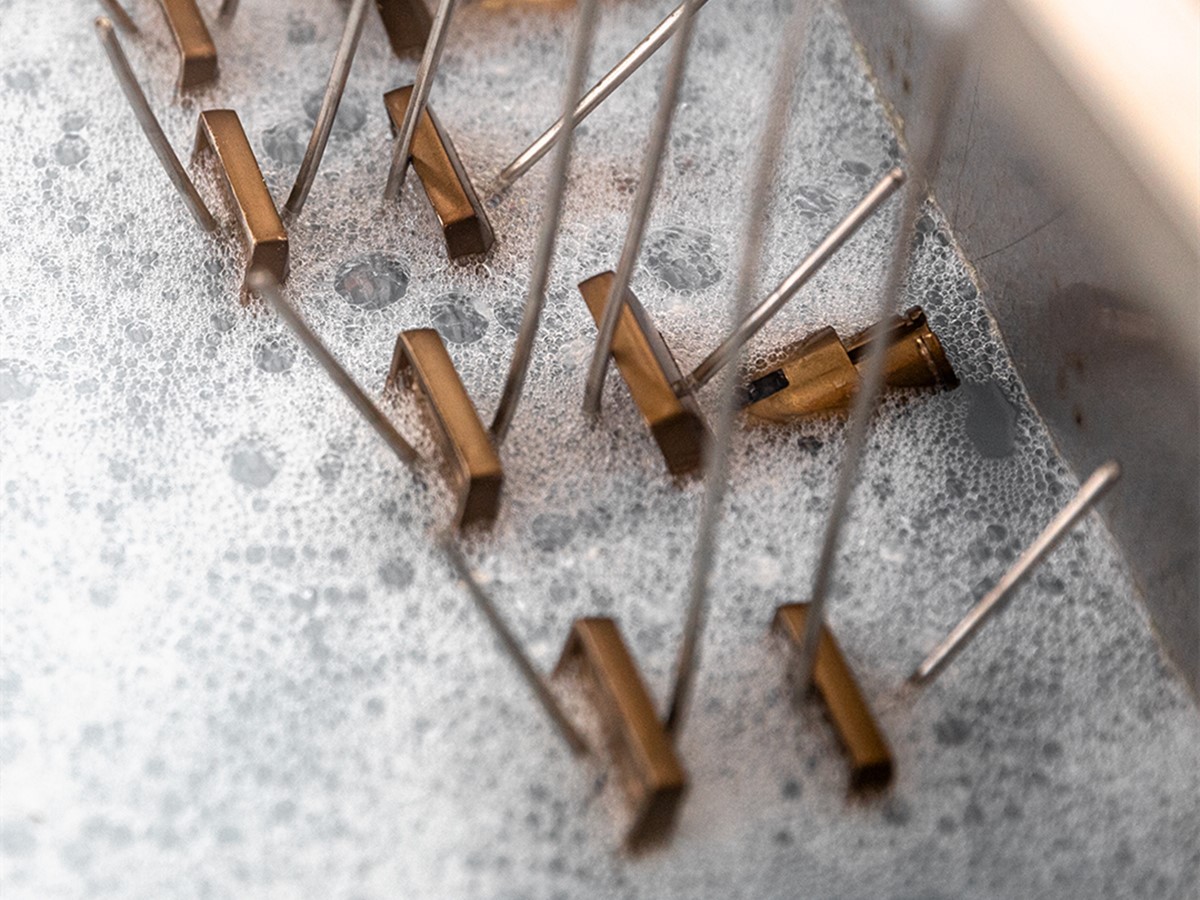

In the die-casting process, in addition to strict requirements for raw materials and production temperature, we conduct specialized oven testing on cast parts. This critical evaluation ensures that each casting meets the necessary standards before advancing to the next stage.

Since we employ high-temperature electroplating, any insufficiency in the density of the raw castings would adversely affect plating quality—often manifesting as micro-porosity on the plated surface, which compromises both aesthetics and performance. Our proactive testing approach guarantees superior surface quality and durability in the final product.

During the machining process, we meticulously measure the machining accuracy of each batch of products according to their specific design drawings. This is critical — if the precision fails to meet required standards, the product may not install correctly or could even malfunction.

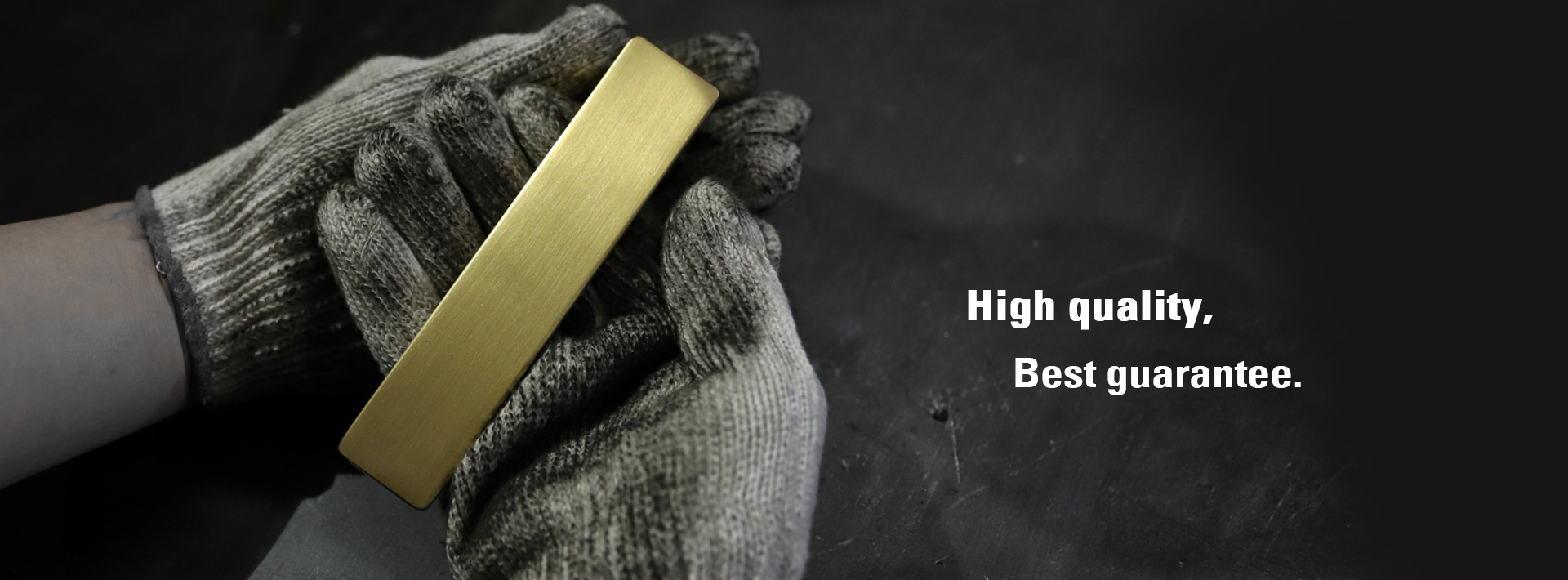

The polishing process primarily removes impurities from the surface of die-cast parts. This improves conductivity during electroplating and results in a better finish.

During this stage, we check for any deformation caused by polishing. We also inspect the surface for minor pores after polishing is completed.

After the electroplating process, we carefully inspect the surface of each plated component.

If obvious scratches, abrasions, or pores are found, the product will be reworked. When necessary, it is discarded directly.

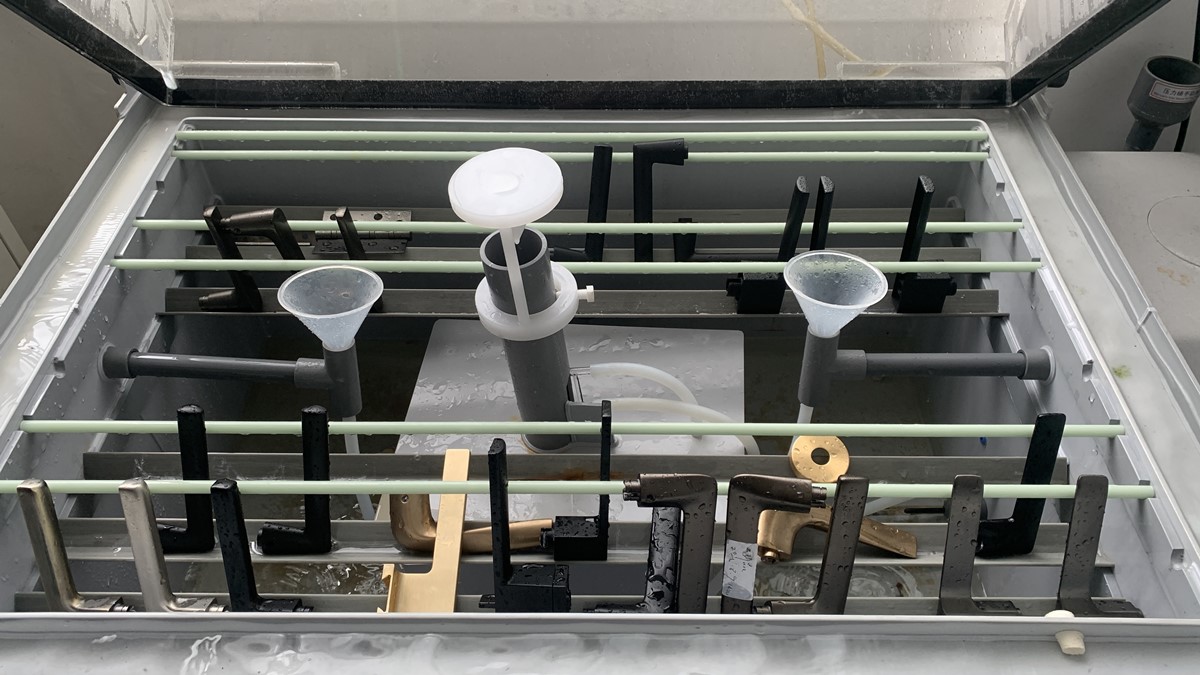

During the assembly and packing stages, workers verify that all materials are complete and correct according to the BOM list.

After assembly, quality inspectors perform a full check, including product function, accessories, packaging, and labeling.

For customized products, photos are taken for records.

Once all checks are completed, a detailed inspection report is filled out to confirm the batch passes and is ready for shipment.

We have a testing team for in house testing every month