Zinc alloy hardware offers excellent value and design flexibility, but its durability is often questioned. The truth is, durability isn’t just about the material—it’s about manufacturing quality. This guide reveals the 6 critical tests that separate high-performance zinc alloy hardware from inferior products, helping you make an informed choice.

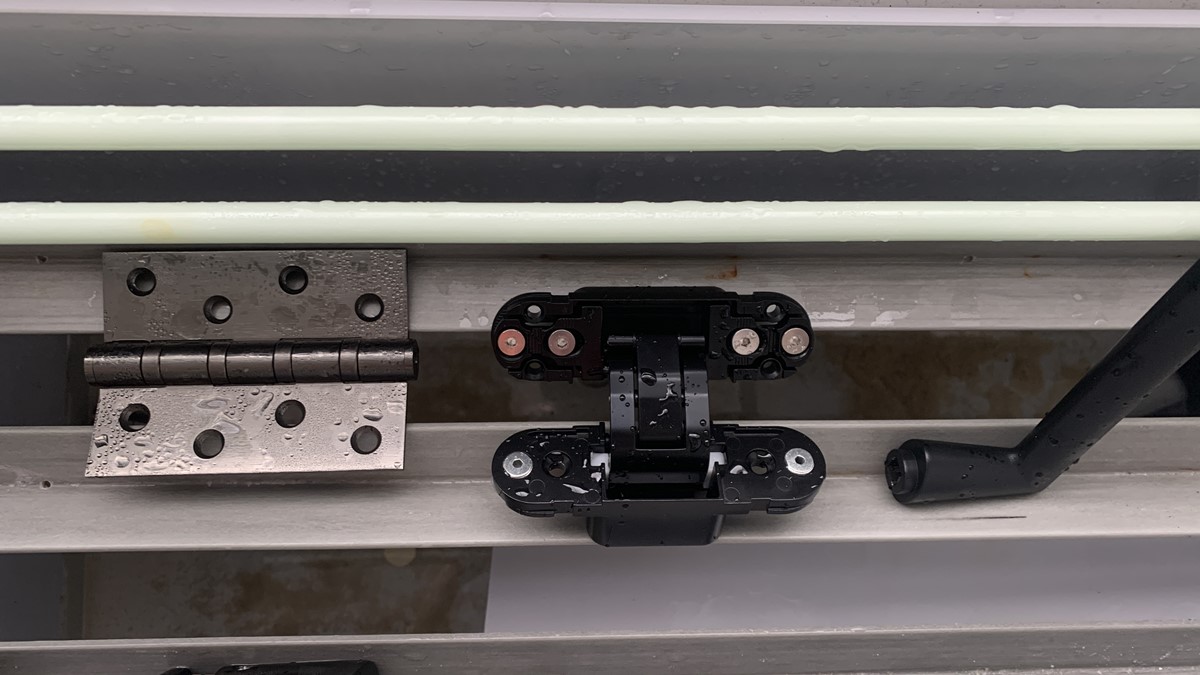

Test 1: Mechanical Strength (The Anti-Break Test)

Purpose: Evaluates resistance to breakage under extreme force or impact.

How It’s Done:

Handles: A static load (e.g., 80kg) is applied to the lever. A quality handle should show no deformation.

Hinges: A vertical force is applied to test the knuckles and leaves for bending.

The IISDOO Standard: We use high-purity Zamak and precision die-casting to eliminate internal flaws, creating a robust internal structure that far exceeds basic requirements.

Test 2: Abrasion Resistance (The “10-Year Use” Simulator)

Purpose: Measures the plating’s ability to resist scratches and wear from daily contact.

How It’s Done: A specialized machine rubs an abrasive wheel against the finish for thousands of cycles.

The IISDOO Standard: Our PVD (Physical Vapor Deposition) finishes are exceptionally hard and uniform. They withstand significantly more abrasion cycles than standard electroplating, ensuring the beauty lasts for years.

Test 3: Salt Spray Test (The Corrosion Benchmark)

Purpose: Simulates harsh, high-humidity environments to test corrosion resistance.

How It’s Done: Samples are exposed to a continuous saltwater mist for a set number of hours.

The IISDOO Standard: While cheap plating fails in under 24 hours, IISDOO components are engineered to pass 72+ hours of neutral salt spray testing with only minimal surface tone change and no red rust. This is achieved through our multi-layer nickel-under-copper sealing process.

Test 4: Fatigue Life Test (The Endurance Race)

Purpose: Determines the operational lifespan of moving parts.

How It’s Done:

Handles: Machines cycle the lever up to 100,000 times.

Hinges: They are opened and closed tens of thousands of times.

The IISDOO Standard: Our in-house manufacturing allows us to integrate reinforced internal structures and precision bearings. This ensures our products operate smoothly and reliably long after the test is complete.

Test 5: Coating Adhesion Test (The Peel-Off Check)

Purpose: Ensures the plating is molecularly bonded to the substrate and won’t flake or peel.

How It’s Done: A cross-hatch pattern is cut into the finish, and special tape is applied and ripped off.

The IISDOO Standard: We achieve the highest grade of adhesion. The plating remains perfectly intact, guaranteeing long-term integrity.

Test 6: Aging Test (The Environmental Challenge)

Purpose: Assesses resistance to UV degradation and thermal cycling.

How It’s Done: Products are subjected to intense UV light and rapid temperature changes.

The IISDOO Standard: Our finishes and materials are formulated to resist fading, chalking, or cracking, ensuring stable performance in both indoor and protected outdoor applications.

The IISDOO Difference: Quality Engineered from the Ground Up

These six tests are not just for show; they are integral to our production line’s quality control. As a manufacturer, we don’t just assemble parts—we engineer them. We control the entire process, from material selection and mold design to precision machining and PVD coating.

This vertical integration allows us to bake durability and reliability into every product we make. It is the foundation of our promise for truly worry-free after-sales service. When you choose IISDOO, you are choosing hardware that has been proven to perform.

Your At-a-Glance Checklist for Durability

| Test | What It Checks | What to Look For |

| Mechanical Strength | Resistance to breaking | No bending or cracking under load |

| Abrasion Resistance | Plating longevity | No wear-through after repeated rubbing |

| Salt Spray | Corrosion resistance | No rust after 72+ hours |

| Fatigue Life | Long-term operation | Smooth function after 100,000 cycles |

| Coating Adhesion | Plating bond | No flaking when tape is pulled |

| Aging | UV & temperature resistance | No fading or cracking |

Conclusion: Look Beyond the Surface

True durability is the result of rigorous engineering and uncompromising quality control. By understanding these key tests, you can confidently select zinc alloy hardware that offers outstanding performance and longevity.

FAQ:

Q: How can I check quality without a lab?

A: Feel the weight—quality zinc alloy feels substantial. Examine finishing details for flaws. Ask the supplier for test reports.

Q: Is zinc alloy suitable for exterior doors?

A: Yes, but only with a high-quality, thick PVD finish that has passed extended salt spray testing, like IISDOO products.

Post time: Oct-17-2025